Understanding the Lens Glazing Process: A Step-by-Step Guide

At Tec-Labs, we believe in transparency and education. Understanding the lens glazing process can help you appreciate the craftsmanship and technology involved in creating the perfect pair of glasses. Here’s a step-by-step guide to our lens glazing process:

Step 1: Prescription Verification

The first step in the lens glazing process is verifying the prescription provided by the optician. This step is crucial to ensure that the lenses are cut to the correct specifications. Any errors in the prescription can lead to discomfort and poor vision for the wearer, so we take great care to double-check the details.

Step 2: Lens Selection

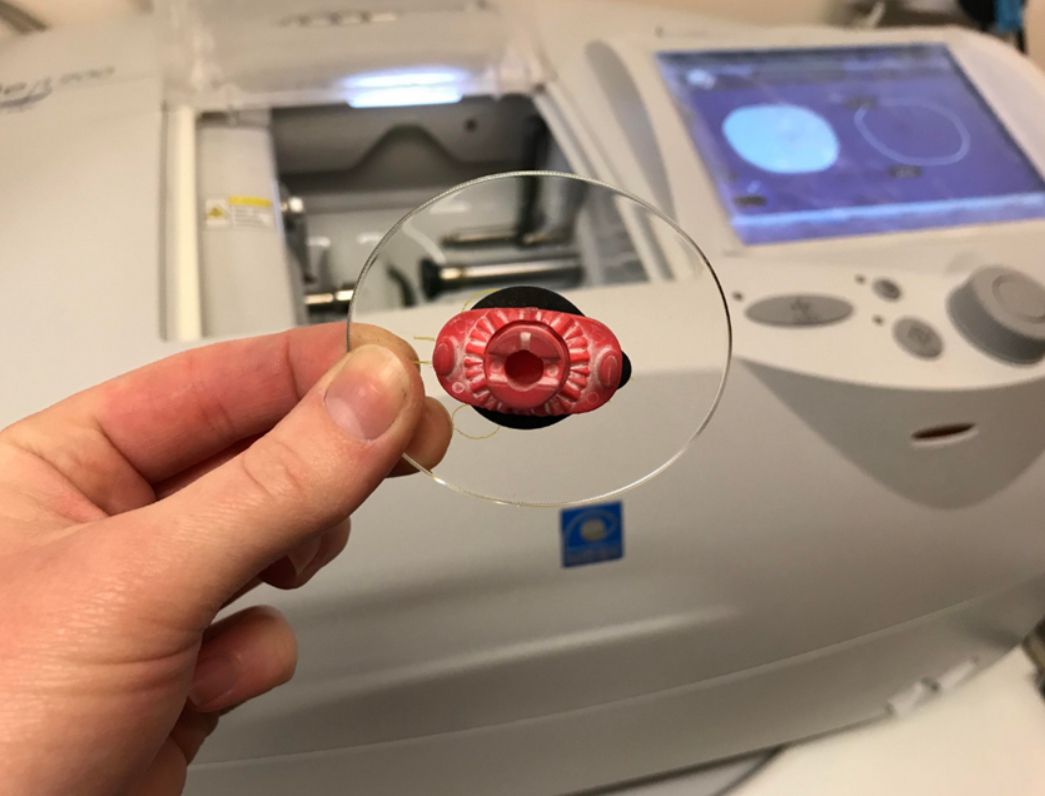

Step 3: Cutting the Lenses

Step 4: Edging the Lenses

After cutting, the edges of the lenses are smoothed and shaped to ensure a perfect fit within the frame. This process, known as edging, is critical for both the aesthetic appearance of the glasses and the comfort of the wearer. Smooth edges prevent discomfort and ensure the lenses stay securely in place.

Step 5: Fitting the Lenses

Step 6: Quality Control

Every pair of glasses undergoes rigorous quality control checks to ensure they meet our high standards. We inspect the lenses for any imperfections or defects and verify that they match the prescription precisely. This step includes checking the alignment, fit, and overall quality of the glasses.

Step 7: Final Inspection

Before the glasses are ready for delivery, a final inspection is conducted to confirm that they meet all quality standards. This includes a thorough check of the prescription accuracy, lens alignment, and overall fit within the frame. Only after passing this final inspection are the glasses deemed ready for delivery to the optician.

Conclusion

By following this meticulous process, Tec-Labs ensures that each pair of glasses is crafted with precision and care, providing optimal vision correction and comfort for your clients. Understanding the lens glazing process highlights the expertise and technology involved in delivering high-quality eyewear. Partnering with Tec-Labs allows you to offer your clients the best possible vision solutions, enhancing their satisfaction and your practice’s reputation.